Microbiology can clean up toxic waste from abandoned mines

Published in the January 20 – February 2, 2016 issue of Morgan Hill Life

By Marty Cheek

Photo by Marty Cheek

Advanced Materials Processing President Dennis Amoroso and his son Adam Amoroso work on a machine that crushes rock into fine powder.

In a nondescript office and laboratory located behind a wedding cake bakery in an industrial building on Tennant Avenue, a team of researchers are working on technology they hope might one day change the world. They’re developing an inexpensive system using microbiology that can be used to clean up the heavy metals in abandoned mines around the world — and convert the soil waste into a cheap and quality nutrient for the agricultural industry.

Advanced Materials Processing President Dennis Amoroso and scientist Dr. Leonard Nanis, with a background in extractive metallurgy at the Massachusetts Institute of Technology, have developed a system they say can take out the atomic-sized particles of gold, quicksilver, mercury, copper and other metals from the billions of tons of spoil of old mining sites around the world. California has about 39,000 abandoned mines sites, which the Department of Conservation conservatively estimates contains a billion tons of waste soil, Amoroso said.

“That mine waste is the residue of what were mining operations over the last century,” Nanis said. “They’ve gotten out all the gold nuggets and all the flakes, it’s all crushed up nice and fine. But still what’s in there, the amount of material gold and silver that makes it worthwhile with our special chemistry.”

That chemistry and microbiology system is a closely-guarded secret worth potentially billions of dollars. Advanced Materials Processing might be giving birth to a new environmentally-smart industry that not only gets the residue of heavy metals out of the dirt, cleaning up toxic-waste sites across the world, but also making “bio-mineralized soil amendments” that will replace the synthetic fertilizers widely used by farmers.

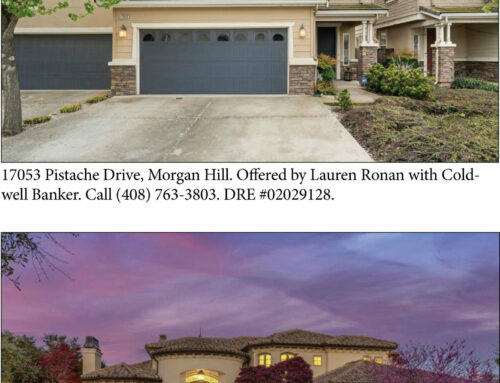

Photo by Marty Cheek

President Dennis Amoroso and Chief Technology Officer Dr. Leonard Nanis in Advance Material Processing’s Tennant Avenue facility.

“These are the natural constituents of rock,” Nanis said. “And when you have the powdered rock mixed with the biological material, inside underneath that root, there’s a whole sphere of activity going on. There are enzymes, there are fungi, and they have little roots that shoot out and specifically get chemicals straight out of the rock and send it to the plant. There’s a whole bunch of things going on. When you use conventional fertilizer right now, it’s a one shot deal. It’s good for one year and then you have to put more on. In the mean time, you’re not enriching the soil. We’re taking the other approach, we’re enriching the soil for more than one year.”

The chemistry used in the processing of the waste soil is natural and non-toxic, Amoroso said.

“It’s very simple. It’s completely an environmentally sound process,” he said. “You can take what comes out of our process and it goes directly into plant nutrition technologies which is a bio-converter group of operations. It’s very, very simple. There is no complexity to any of this. You pick the dirt up and process it, put it into the bio-converters, take it out a few hours later and it goes on to the ground.”

Currently the soil enhancement material created in the process is being tested by growers including Church Brothers, Yamamoto Almond Growers and Holloway Corporation, he said.

“Huge, huge orchards and growers all over the state of California need this stuff desperately, and those are the words they use,” Amoroso said. “The yield per acre will go up. The soil will become completely healthy. The microbial action goes from 18 inches deep to four feet deep. They’ve confirmed this.”

The system is similar to one used in a rain forest where plant life and microbes work together to create a lush and carbon-dense vegetation environment, he said. The microbial action in the soil is what creates all the interactive activities that literally use electro-chemical process to break down minerals that supports the plant growth and make the forest sustainable year after year, century after century, he said.

“Why does a rain forest work? No one is out there fertilizing the damn thing,” Amoroso said. “It’s because the micro-nutrients that are the minerals, that are the metals in the soil, get used by the plant. The plant dies and goes back into the soil. The microbes make it decay. New microbes come along and turn those minerals back into usable nutrients for the plants, and new plants grow.”

When humans come into a huge forest and cut down the top crop and remove it so that the plants don’t decay and release the nutrients back into the soil, it stalls the cycle and the forest microbe-plant mutual benefit stops.

“They’re suppose to be getting those micro-nutrients from the ground. The miners came along in California and they pulled it up to the top of the surface,” Amoroso said. “Now here it is available, full of micro-nutrients. What we do is rebuild the soil and continue to feed plants out of these micro-nutrients mine waste that came from 400 feet in the ground.”

Government agencies are interested in the process because, if it works on an economically-sound basis, it could transform thousands of acres of toxic-waste laden land and Superfund sites throughout the United states. The men have had meetings with representatives from the Department of Conservation, Department of Toxic Substance Control, Water Resources Board, Air Resources Board, Bureau of Land Management and the California Lands Commission.

“All these agencies have to do with mine waste because it affects their sphere of influence,” Amoroso said

One of the Bureau of Land Management’s biggest problem is in the Kern County town of Randsburg which has a massive pile of mine waste that needs cleaning but is too costly to do so using conventional methods. Many of the abandoned mine properties in the Gold Country such as Placer and Sutter counties also have piles of spoil that are toxic-waste hazards.

“They (the Bureau of Land Management) said they would be happy to support all of our efforts to getting mine waste out of the environment,” Amoroso said. “As the water, the acid rain, runs off these piles of mine waste, it gets into the water shed. These toxins are called heavy metals. They’re toxic if they go directly from the rock into the water. But if they travel through plants, they no longer are toxic, they become something that is called micro-nutrients and turn into great produce.”

The company is now seeking about $5 million in funding to help it ramp up its operations and build a 50,000-square-foot plant in an optimal area where the mine waste is most concentrated in California. If it grows successfully in the coming years, it sees the potential of creating thousands of jobs that will help local economies throughout California and other states. The company has also got inquiries about their process from people in Argentina, Turkey and Brazil. It plans to keep its headquarters and research center in Morgan Hill.

Other benefits from Advanced Materials Processing’s system includes cutting down on the need to extract the millions of tons of natural gas for use yearly as a feed-stock in making ammonia-based fertilizer for the agricultural industry, he said. And, unlike synthetic fertilizers, the soil enhancement substance will not get into water supplies such as aquifers.

“You put synthetics in the soil, 30 percent of the synthetics get used up by the plant, 70 percent finally end up leaching down into the ground water,” Amoroso said. “That’s why the Delta has all of those hyacinths growing over the marinas and stuff because it’s so full of synthetic nitrates.”

The more natural process allows “colonies” of bacteria in the soil to increase and create more nitrates needed to support the growth of the plants, he said.

The company purchased 10 million tons of mine waste from private owners of abandoned mines in Nevada to develop their system. They’re interested in doing business in California because areas in the Golden State where the abandoned mines are located have potentially some of the highest development real estate value — if the land can be cleaned.

“We can come to the land owner and we do this for free, it doesn’t cost them a dime,” Amoroso said. “And they make money off their mine waste. So they can either do a deal with us to develop the property with us or they can just sell us the property out right.”

One obstacle the company faces is investors’ concern that Advanced Materials Processing’s system might be too good to be true, Nanis said. That’s why the company is focusing on the soil enhancement aspect of the technology rather than the more psychologically tantalizing extraction of heavy metals such as gold, silver and copper.

“There’s a psychological barrier when you tell people you’re going to get gold out of that pile of dirt because it sounds like a scam to them and people have been burned many times by that story,” he said.

The system, if it proves to work on a large scale, will get investors interested in saving the natural world from the pollutants of human industry — with the bonus of creating a product that helps feed the people of the world, Amoroso said.

“We’re far more interested in the business of cleaning up the environment, getting the gold out of it, and providing a soil amendment for the farmers so that when we produce food and eat it, it feeds our bodies well,” he said. “As we’ve evolved, we found that the fertilizer was more exciting to investors than the gold ever was. People want to invest money in something that has benefit to mankind, not just to make money.”